Impact crusher is widely used in mine production because of its simple structure, easy operation, good grain type and cheap price. The production efficiency of impact crusher directly affects the user’s profit. In production, if the operation is not proper, it will not only affect the production efficiency of impact crusher, but also may bring damage to the equipment. In the operation of impact crusher, what are the operation points of impact crusher?

Impact crusher

Feed size: 700mm

Production capacity: 30-850t/h

Suitable materials: limestone, pebble, granite, basalt, dolomite, and coal gangue.

First, check the equipment before starting

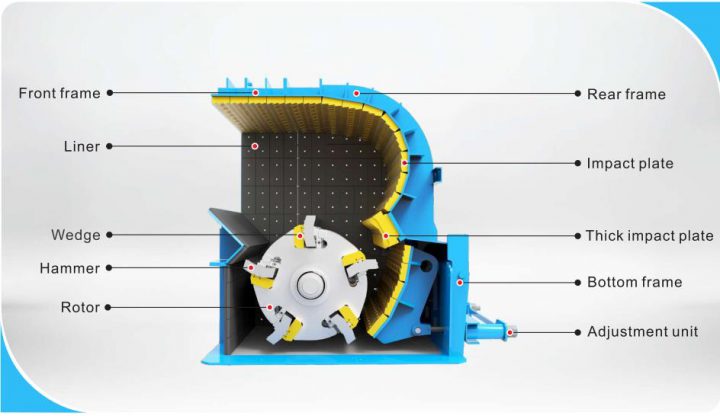

1.Strictly check whether the motor anchor bolts, body bolts, bearing seats, bolts at the protection plate and other fixed parts are loose.

2.Check whether the fixed parts of the impact plate are loose and broken.

3.Check the inner of the equipment, such as whether the wear of the plate hammer is serious, because the plate hammer has a great impact on the discharge particle size. It should also check the situation of other vulnerable parts, including the degree of wear, whether there are cracks and defects.

4.Confirm the next process. The impact crusher cannot work until the belt conveyor and dust collector normal operation.

Second, reasonable adjustment of impact crusher and feeding.

Third, timely replacement of wear-resistant parts.

For more details about the impact crusher, please consult Luoyang Dahua Heavy Industry, our website is www.lydhcrusher.com, the technical manager will answer you online.