When designing a new sand and gravel production line, it is essential to comprehensively consider multiple critical factors, including process flow design, equipment selection, environmental protection requirements, and operational cost control.

I. Production line process flow

Preliminary research and design

- Conduct comprehensive target market research to clearly establish the matching rate between product specifications and market demands, thereby preventing unnecessary increases in subsequent technological transformation costs.

- Determine the crushing process (dry method or wet method) and equipment configuration by taking into account the characteristics of raw materials, such as the hardness differences between limestone and granite.

- The site selection should be close to the raw material extraction area, make use of the natural terrain to reduce the cost of civil construction, and adhere to land use and environmental protection regulations.

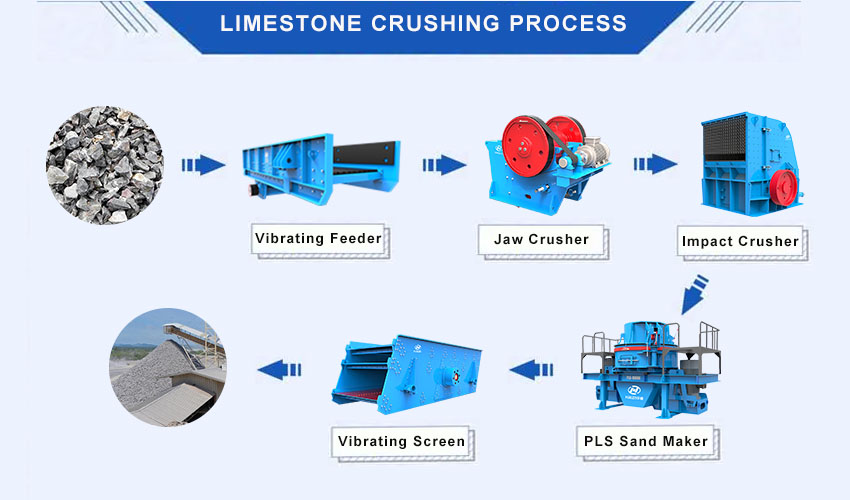

Core process flow

- Raw material processing: Blasting mining → uniform feeding by vibrating feeder → coarse crushing by jaw crusher → medium fine crushing by cone/impact crusher → screening by vibrating screen → return material for re-crushing or enter the sand making process.

- Sand shaping: Vertical shaft impact crusher for mechanism sand shaping, wet process can be combined with sand washing equipment to improve finished product cleanliness.

- Finished product classification: 0-5mm manufactured sand and aggregates in various particle sizes can be classified by using multi-layer vibrating screen.

II. Customer cases

550t/h EPC Project for Basalt Crushing Production in Indonesia – The basalt crushing production line is designed and manufactured by Luoyang Dahua and Singapore Trimax, finished product is 0-5-12-25-40 mm.

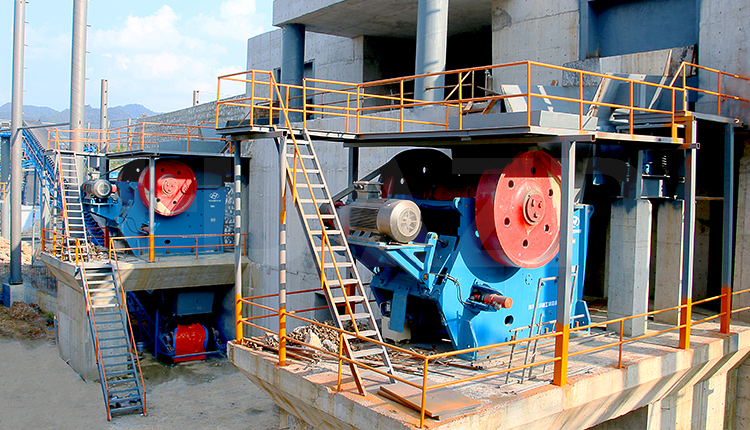

2000t/h EPC Project for Limestone Crushing Production – This EPC project is for limestone crushing production with capacity of 2000t/h. Adopt the crushing process of three sections and one closed circuit: jaw crusher + cone crusher + cone crusher.

III. Matters and attentions

- The selection of equipment should be determined by considering the hardness of the raw materials and the soil content, thereby preventing excessive crushing or material blockage.

- Regular maintenance and servicing, including the inspection and repair of the lubrication system, are essential for ensuring uninterrupted production.

- When establishing a new production line, it is essential to strike a balance between the initial investment and long-term benefits. It is advisable to collaborate with a professional manufacturer to develop a comprehensive plan and optimize the layout by taking into account both on-site conditions and policy requirements.

Luoyang Dahua Heavy Industry is a high-tech enterprise with research & development production, sales, and service. The mobile crushing station has been successfully applied in domestic and foreign mine crushing projects. The company has a professional R & D team, a strong after-sales team, from the equipment selection, site inspection, equipment manufacturing, installation, commissioning, delivery and other aspects for your service.