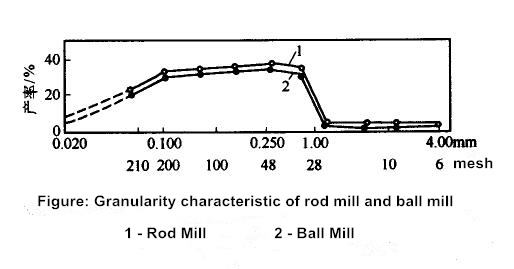

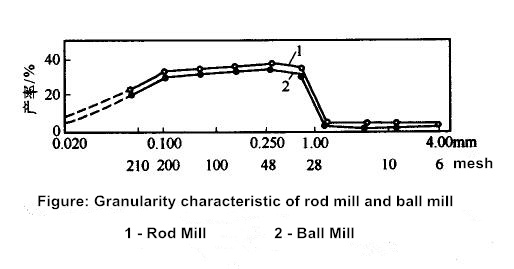

The process feature of rod mill is even grain size, less coarse and big particle and less slurry content. The granularity of rod mill products and ball mill products is shown in the figure. Rod mill has the function of selectable crushing coarse particle and selectable protect fine particle, which generates even particle size. Ball mill selectable crushing effect is bad, and the product particle size is uneven with more too coarse and fine particle.

According to the crushing characteristic of both mills, we can know the application scope of rod mill:

(1) In order to prevent more crushing of valuable mineral at magnetic separation plant and reselection plant of tungsten-tin deposit and other rare metal minerals, normally use rod mill in the process of coarse grinding.

(2) Rod mill can replace the short head cone crusher as the fine crushing machine in some cases. When dispose soft or not too hard ore, especially the ore with more slurry and viscidity, if use short head cone crusher, it will generate more dust and cause crusher block. If use rod mill, it can crush the ore with particle size 20-30mm into 6-10 mesh, which reduce the cost and simplify the fine crushing dedusting.

(3) When in coarse crushing process, the products granularity are 3-1mm, the production capacity of rod mill is large than the same specification of ball mill. When in the fine crushing process, the granularity is below 0.5mm, the production capacity is smaller than the ball mill.

Although the selectable crushing effect of ball mill is bad, it can be widely used in grinding various ore, no matter the coarse grinding or the fine grinding.