What Equipment will be used in the Sand Making Production Line?

The sand making production line comprises of crushing, sand making, screening, sand washing and other components.

The sand making production line comprises of crushing, sand making, screening, sand washing and other components.

Luoyang Dahua can provide comprehensive artificial sand making production line equipment and projects turnkey solutions with an annual output of 30,000 – 8,000,000 tons.

The pebble crushing production line has the features of high automation, high crushing ratio, low operation cost, energy saving and fine granularity. The production capacity is 30-1000 t/h.

The main equipment generally used in the secondary crushing process is: vibration feeder - primary crushing (generally jaw crusher) - secondary crushing (impact crusher, cone crusher, or vertical shaft impact crusher) - vibrating screen - finished stone

Vibrating screen is an important equipment in stone crushing production line. In this text, we will analysis the reasons for poor vibrating effect of vibrating screen.

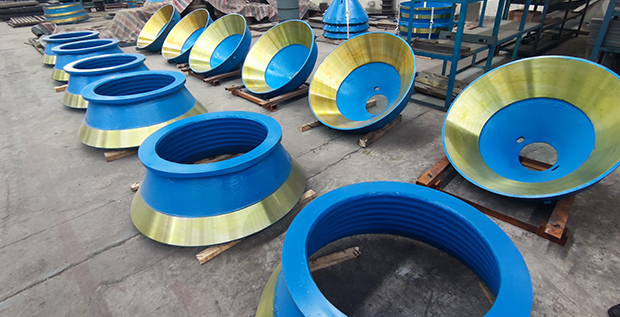

The main parts of stone crushers are jaw crusher tooth plate, toggle plate, eccentric shaft, cone mantle & concave, hammer crusher hammer head, and other components.

With the development of sand making industry, the models and parameters of sand making machine are gradually enriched. Currently, impact sand making machines, cone sand making machines, and high-efficiency sand making machines are prevalent equipment for producing sand.

Impact crusher blow bars (also called hammers) are the main wear item of horizontal shaft impact crushers.

Luoyang Dahua hammer heads are made of alloy steel, high manganese steel, cast steel and bimetallic composite materials by forging or casting methods for a one-time formation.

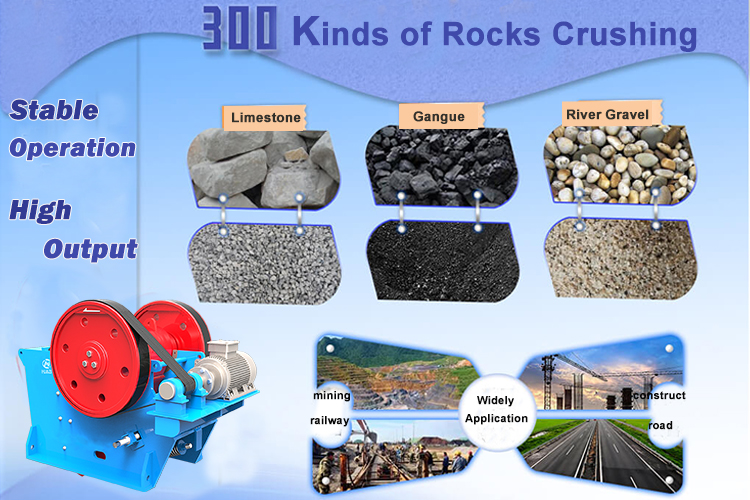

The stone crusher is extensively employed in industries such as mining, construction, railway, highway. Choosing the appropriate stone crusher model is a critical aspect of the selection process.